Are you regularly dealing with 3D printing?

Then, you must go through a popular debate of 3D printer FFF Vs FDM. Both of these technologies improve the functionality of 3D printers. Besides, their features are almost identical.

Consumers get confused in most cases and assume these as the same technology for 3D printing. So, it’s a tough task to make a perfect choice between 3D printer FFF Vs FDM.

Getting perplexed? Don’t worry.

This article presents a detailed comparison of these printers so that you don’t get puzzled while making your choice. Let’s dig it deeper.

- What Is 3D Printing

- Are There Any Hassle For These Names

- FFF 3D Printer

- Best FFF 3D Printer

- FDM 3D Printer

- Best FDM 3D Printer

- Working Principle Of FFF/FDM

- What types of Extruders Are Used In 3D printing

- Pros And Cons Of FFF

- Pros And Cons Of FDM

- How To Compare Between FDM And FFF?

- FAQs

- Final Verdict

What Is 3D Printing

3D printing is a specific printing method where 3D objects are built through a layering method by using CAD. It involves different layering elements, like thermoplastics, bio-materials, etc.

This printing technology delivers high-quality print in the case of colour, size, shape, robustness, etc. Its outstanding flexibility and functionality make it compatible with different sectors. Such as education, art, jewellery, prototypes, etc.

You can check “How To Program A 3D Printer” to Get a better understanding of 3D printing.

FDM and FFF are the most widely used 3D printing technologies. These processes have immense similarities, along with some considerable variations.

These two have a trademark issue that creates the main difference. That’s why users get confused frequently. Some people think that these two are the same, and others think completely opposite.

Are There Any Hassle For These Names

Newbies face hassle due to the debate between 3D printer FFF Vs FDM.

Do you know how the consumers get troubled?

It creates a poor impression of 3D printing due to miscommunication. Besides, the wrong notion makes the users puzzled while thinking of FFF or FDM 3D printing.

So, how do you get relief from this?

Don’t worry. We are here with the history, functioning, pros and cons of these two technologies. Let’s have a look.

FFF 3D Printer

FFF (Fused Filament Fabrication) is an effective 3D printing technology that builds a multilayer object through the deposition of melted materials layer by layer. It involves plastic-made filament during printing.

This technology has existed in the 3D printing world since 2005. It was a project of RepRap.

Here, the entire process is performed in an effective way through the use of a slicing software. That’s why it can ensure quick manufacturing of 3D objects in a highly controlled atmosphere.

You can check Amazon for more details and prices.

Best FFF 3D Printer

- FlashForge Dreamer Desktop 3D printer

- MakeGear M3

- Prusia I3 MK3S

FDM 3D Printer

FDM is the short form of Fused Deposition Modelling. This technology is compatible with high-level 3D printers and production-grade thermoplastics. It delivers durable, flexible, and stable printing.

Its beginning was in 1989. Mr. Scott Crump was the founder of Stratasys Ltd. He patented FDM technology. From the beginning, this process ensures outstanding print quality and repeatability in 3D printing.

For more updates: Amazon

Best FDM 3D Printer

- Creality Ender 3 Pro

- Vivedino T-Rex 3

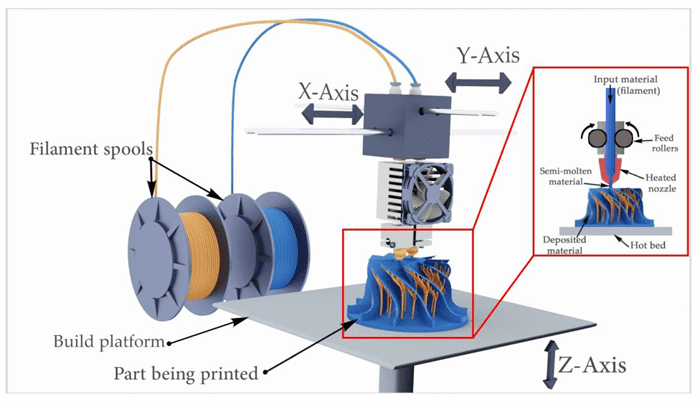

Working Principle Of FFF/FDM

Have you ever thought of how 3D printers function?

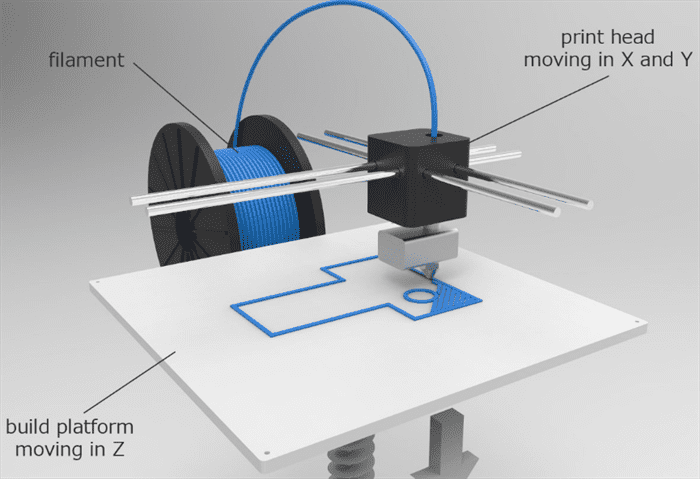

The basic function of the FFF/FDM printer is not very complicated. The entire operation starts with making 3D models by using a modelling program. Then FDM or FFF printers build a physical structure of 3D objects.

These printers lay down the filaments through a nozzle or heated extruder. Then, these warm layers are placed on a flat printing platform.

This process can vary due to the modelling and extruder types. The most used model types for 3D printers include-

Delta 3D printer Model

Here, the printing bed remains stable but extruders can move across all axes. This model uses the cartesian coordinates for 3D printing.

Cartesian 3D printer Model

This popular model keeps the extruders moving in the X and Y axes. But the printing bed can move on the Z-axis. It also incorporates the cartesian coordinates.

Polar 3D printer Model

Unlike other models, it uses polar coordinates. That means this model is not dependent on the set origin of points. But each point has a relation to the variable pole.

What types of Extruders Are Used In 3D printing

3D printing involves varieties of extruders. Such as

- Pallet Extruder: It utilises plastic granules

- Filament Extruder: It uses a thermoplastic filament

- Paste Extruder: It is compatible with ceramic.

Pros And Cons Of FFF

Pros

- High printing speed

- Low-cost materials

- Easy replacement of materials

- Compatibility with a wide variety of materials

- Compact design

- Convenient setup

- Cost-effective printing

Cons

- Restriction for nozzle size

- Comparatively low durability

- Limitation in the strength of finished products

Pros And Cons Of FDM

Pros

- Excellent control of temperature change

- User-friendly

- Usability of dual extrusion

- Cleanness in printing

- Easy operations

- Compatible with complicated designs

- Supportive of thermoplastic materials

- Eco-friendly

- High durability

Cons

- Lack of robustness in layer junction

- Expensive

- Heavy post-printing

- Complicated designs for detailed output

How To Compare Between FDM And FFF?

Print Chamber

FDM 3D printers contain a print chamber to ensure high heat (around 320⁰C) atmosphere in a hot build platform. It improves the robustness of 3D printing.

But FFF technology is not involved in any heated chamber. That’s why there is a rapid conversion of temperature from hot to cold.

Filament Quality Control

FDM ensures optimum quality control for high-volume 3D printing. This technology incorporates a laser to maintain high accuracy in diameter. Besides, FDM 3D printers are designed according to the quality and traceability guidelines of ISO.

So, do you need to worry about print quality?

We don’t think so.

FFF technology can’t handle the filaments with high precision like FDM. So, it hampers the usability of FFF 3D printers, isn’t it?

Tolerance

Fused Deposition Modelling is reputable for high mechanical tolerance. FDM 3D printers can handle mechanical loads with excellent efficiency. They ensure the accuracy of 0.127 mm.

This tolerance enables the user to accommodate part applications that are mandatory in high-class engineering-grade prototypes.

On the other hand, FFF can’t maintain consistent tolerance in all cases. That’s why consumers prefer FDM to FFF in 3D printing where mechanical tolerance is a vital issue.

Functionality

Fused Filament Fabrication involves the nozzle of 3D printers to heat the molten filaments. Here, the enclosure is discarded during the heating.

So, the filament remains in contact with air. Air decreases the filament temperature quickly resulting in the reduction of mechanical strength and print quality.

But FDM technology ensures premium functionality during 3D printing. The entire heating of FDM 3D printing occurs in a closed enclosure. That’s why the print resolution gets improved.

Thermal Management

In this case, FDM 3D printing delivers more dependable performance compared to FFF. These printers are supportive of around 90⁰C.

FDM printers consist of a print chamber to maintain the consistency of temperature. This print chamber is effective for handling a continuous filament flow from an extruder that works at a high temperature.

The FDM printer parts take care of mechanical pressures while going through a hot atmosphere. Besides, they act to strengthen the layer adhesives and avoid wrapping the printer. That’s why 3D printing has become more convenient.

On the contrary, FFF printers deliver the filament from a hot extruder to the platform through a cold environment. This change of thermal states from hot to cost causes producing residual stresses. It hampers the print quality to a large extent.

So, it is evident that FDM offers better thermal management than FFF in 3D printing.

Workability with Advanced Plastics

FDM printing technology can deal with many high-quality plastic materials. Such as Nylon, Ultem, Polycarbonate, Peek, etc. It can handle these plastics due to having a print chamber.

But FFF 3D printers offer compatibility with comparatively low-class plastics. That’s why these printers can keep the printing cost minimum. So, if you don’t have budget issues, you should go for FDM printers for their capability of handling advanced plastics.

Dual Extrusion

FDM printers incorporate dual extrusion technology in 3D printing. Do you know how this technology impacts printers?

The dual extrusion ensures the easy creation of complex geometry of 3D printers. It enables the designer to use soluble supportive materials that ensure smooth finishing.

Modern FFF printers also offer dual extrusion technology. They support PVA (PolyVinyl Alcohol) that requires a few minutes to get dissolved in liquid.

So, we can say that it’s a tie in this event.

FAQs

- Why Are 3D Printers So Slow?

3D printers deal with different layers of an object and they act layer-by-layer. As 3D objects consist of multiple layers, it takes a huge time for printing. That’s why 3D printers are a little bit slow.

- Are Resin Printers Cheaper Than FDM?

Yes. FDM printing is more economical compared to resin printing. Usually, you need to frequently change the resin and resin tanks of resin printers. That’s why their printing cost increases. But FDM is free from such hassles.

- Is FDM Printing Strong?

Yes. FDM printers are compatible with plastic materials. They make these strong materials semi-liquid through sufficient heat. Besides, the filament used in FDM functions in the wire form. So, you can consider FDM printing as strong.

So, what should be your choice?

Final Verdict

While comparing 3D printer FFF Vs FDM, it is clear that FFF technology can make your printing more accessible than FDM. But FDM ensures outstanding performance in the case of temperature control, plastic compatibility, etc.

So, you need to choose wisely concerning your printing requirement. Our verdict goes to FDM technology because of its immense positive points.

We hope this article will help decide between these 3D printing mechanisms without any confusion. If you have more queries, feel free to contact us any time.

Happy printing.