Confused and can’t differentiate between 3D printer rails vs rods? There can be many differences between rails and rods. They also work differently from each other. But one of the most important things they both did is making the 3D printer print smoother.

Now, to learn the differences between 3D printer rails vs rods, read the whole article and you will get a good overview of it.

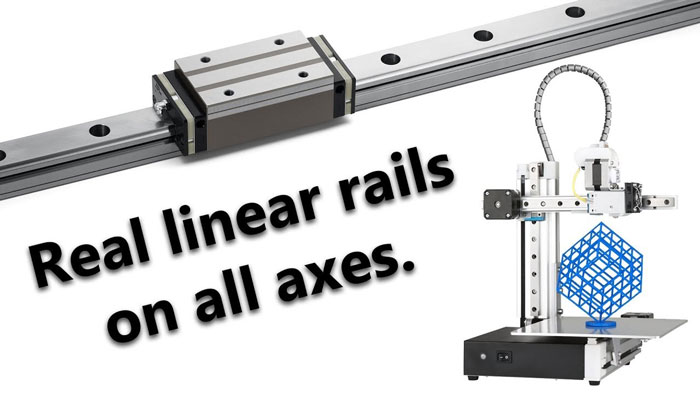

3D Printer Linear Rails

Linear rail is a stiff piece of metal that got machined. There are steel rails, stiffs, carriage utility mechanisms, etc. Interestingly, there is a bearing block that contains ball bearings. Now, how do these ball bearings work?

Because of the ball bearings attached to that block, the block can move the whole rail very smoothly. They go into a continuous loop inside of the block. Now, do you need grease for these bearings? Absolutely, to make the ball bearings work smoothly for a long time, grease can help a lot.

For a better motion system, 3D printers linear rails help a lot like good motion system, better performance, etc. There are many popular 3D printers rails available in the market. But always look for high-quality material.

If the comparison is about stiffness, linear rails will be at the top. The total construction of the 3D linear rails is top-notch. And, because of the materials used to manufacture this rail, the reduction of backlash and ringing artifacts have gone less.

3D Printer Linear Rods

Many say linear rods are the alternative to using linear rails. But is it true?

There can be various types of linear rods available because of the lengths and diameters’ partialities.

The linear rods are made of steel. The hardness of rods is very enhanced too.

In the traditional rod setup, you will not find the rods always straight. Like linear rails, there are ball bearings with a carriage utility mechanism too. But these ball bearings do not move around. Instead of that, they just roll in standing in one place.

Differences Between 3D Printer Linear Rails VS Rods

Comparatively, there are a lot of differences between 3D printer linear rails vs rods. Before designing the 3D printer, the first thing to do is to take the decision on which one to choose between rails and rods.

Now, there can be different factors of linear and rods that you can differentiate.

| Linear Rails | Linear Rods |

| 1. You can use linear rails to make a good compact 3D printer design. But you also need to provide support to the rails. | 1. There must be a pair of linear rods to make a good 3D printer design. The plus point is, they do not have any extra support. |

| 2. Depending on the rail width, the cost is measured. Here is an overview-5 mm – 40+ cents/mm10 mm – 55+ cents/mm12 mm – 45+ cents/mm15 mm – 60+ cents/mm20 mm – 70+ cents/mm | 2. Depending on the diameter of a rod, the cost classification is done. 5 mm – 15+ cents/mm10 mm – 20+ cents/mm12 mm – 15+ cents/mm15 mm – 18+ cents/mm20 mm – 20+ cents/mm |

| 3. The dynamic load capacity of a linear rail carriage is very complex. For different lengths of linear rails, the dynamic load capacity can be 60-1000 kg or more. | 3. Rods dynamic load capacity is low. For similar diameters like linear rails, the dynamic load capacity of linear rods can be 30-150 kg or more. |

| 4. Normally, the maximum speed of the bearings of linear rails can be around 2 meters/second. | 4. The maximum speed of the bearings of linear rods can be around 4-5 meters/seconds. |

| 5. The required parts of a linear rail are hex slot screws, supporting body(aluminum extrusions), etc. | 5. The required parts of a linear rod are shafts, structural beam, etc. |

| 6. They are more expensive than linear rods. As the gadget is of premium quality, the price is also premium. | 6. The price of linear rods is almost 4-5 times less than linear rails. So, if you have a tight budget, then you can go for linear rods too. |

| 7. As the linear rails have ball bearings into them, they are needed to be cared for properly. Moreover, if the linear rails fall once from hand, the ball bearings inside it may roll out. And once this happens, it will lose consistency in motion. | 7. Linear rods can be hard and not fall that easily. So, the ball-bearing falling chance is close to none. |

| 8. Linear rails do not rotate the carriage. They work simply and lightly. Also, as it moves line by line smoothly, the precision is higher too. It will print out the papers properly with a tighter tolerance. | 9. The tolerance tightness is way less for linear rods than linear rails. Also, linear rods allow the rotation of the carriage too. The 3D printing ringing is also higher than 3D linear rails. |

Frequently Asked Questions

1. Are Linear Rails Stiffer Than Linear Rods?

Yes, linear rails can be stiffer than linear rods. Now, this difference can occur because of differences in the mounting method of both systems.

Linear rails take the whole advantage of not only the stiffens needed in the mounting surfaces but also take an additional amount too. Because of that, it uses extra screws per unit length.

But it does not apply to linear rods. Because they get smooth support. The manufacturers make them this way so that they could be stronger, not bendable.

That is why linear rails are stiffer than linear rods.

2. Are Linear Rails Worth It For Ender 3?

Because of the smooth motion and precise movements, many people will choose linear rails. Because of that, linear rails are thought to be worthwhile for Ender 3.

Now, if you know the process of programming a 3D printer, then you may understand how linear rails can improve print quality. The same will do for Ender 3 too.

3. What Can Happen If 3D Printer Rods Are Not Aligned Properly?

The 3D linear rods inside the printer have some ball bearing too. But unlike 3D rails, these rod printers’ ball bearings do not provide the same output. They do not travel around and spring essentially. Moreover, they will only roll in one place.

If the ball bearing of your 3D printer rods are not aligned properly, the ball bearing can easily come out of the system. So, this will create more trouble than before.

Normally, 3D rods will create a bit of sound if you slide it side by side. If you do not align it properly, it will create even more sound and will not function properly too. So, keep it in mind, if you are buying a 3D printer rod, you should know the proper way to align it.

Also, do not forget to put grease into the ball bearing. There are different types of grease you can get in the market. Now, what can happen if you do not put grease inside the rod?

This can lead your rods alignment scrawny. Along with that, it can break the rods holding system too.

Final Words

Linear rails or rods, whichever it is, both have their own advantages. But, if you want a smooth printing system, then you may go for linear rails. Also, you may also like linear rods too.

Hope you have a good understanding of these two machinery metals. But if you are still confused about any part of 3D printer rails vs rods, then you may ask us.