Thermal printers bring tremendous development to the printing world. The operating principle of both thermal printers ensures high-quality printing.

Do you know what two types of thermal printers exist in the market or their pros and cons?

Don’t worry. We are here to inform you of the ins and outs of thermal printer types. We hope it will significantly benefit you while dealing with thermal printers.

Let’s make a move.

- What Is A Thermal Printer?

- Classifications Of Thermal Printers

- Direct Thermal Printer

- Thermal Transfer Printer

- Major Parts Of A Direct And Thermal Transfer Printer

- How Does a Thermal Printer work?

- How Do You Compare Direct Thermal And Thermal Transfer Printers?

- Thermal Printer Advantages And Disadvantages

- What Are Thermal Printers Used For

- Thermal Printers In Color Printing

- Warnings

- FAQs

- Infrared and visible light thermal papers are the most-used papers for thermal printing.

- Conclusion

What Is A Thermal Printer?

A thermal printer is a worthwhile printer that allows digital printings. It is different from traditional printers in its printing process. This printer never utilizes toner or ink to produce images on paper. So, how does a thermal printer print?

Usually, this unique printer uses thermal paper and an electric heater while printing. It is free from ribbons and cartridges that makes this printer cost-effective for the manufacturer.

Besides, it involves printing software that allows you to edit images and improve print quality.

Its noise-free services and rapid monochromatic printing make it popular in various fields. Thermal printers have significant use in banks, grocery, and commercial offices.

Classifications Of Thermal Printers

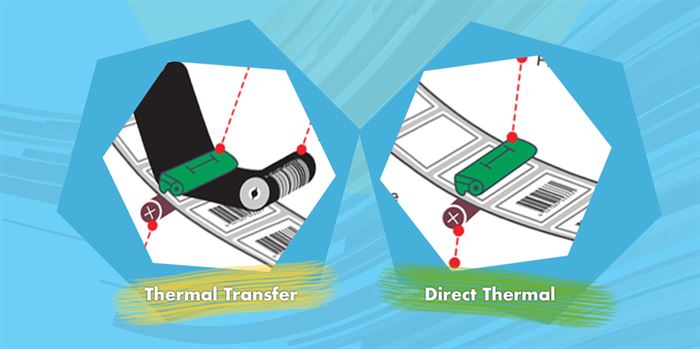

When you are thinking about thermal printer types, two names must go through your mind. These are

- Direct thermal printer

- Thermal transfer printer

These printers are widely renowned as thermal printers. Both of them offer specific features to optimize thermal printing.

But what are the specifications of these two types of thermal printers? Again, how do these printers differ from each other? Let’s dig it deeper.

Direct Thermal Printer

Direct thermal printers are effective printers where printheads and label materials have direct attachments. These printers incorporate the printheads for heat generation. Most noteworthy, direct thermal printers don’t deal with multiple colors during printing.

Besides, they consist of versatile ink ribbons that enable these printers to change the thermal paper colors. Its working principle is not supportive of reusing thermal papers.

Thermal Transfer Printer

A thermal transfer printer consists of a thermal ribbon in the middle of the printhead and label. Unlike direct thermal printers, this printer supports the use of resin or wax ribbons.

This type of thermal printer allows multiple uses of thermal paper. Here, the heat-sensitive papers are transparent and expensive. But these films provide outstanding performance in thermal printing.

Major Parts Of A Direct And Thermal Transfer Printer

Have you ever been amused to think how these two types of thermal printers deliver high-class performance?

Direct and thermal transfer printers are composed of high-quality materials. Their parts are highly durable and functional enough to ensure outstanding printing on thermal films.

Do you know about the major parts of these printers? Let’s have a look.

Electric Coil

This part generates heat in both thermal printers. In the case of direct thermal printers, an electric coil provides heat to the printheads to turn the thermal paper into black.

Again, this coil acts to melt the wax in thermal transfer printers through adequate heat.

Printhead

The printhead is a crucial part that contains the electric coil. It regulates current conduction through this heating material. Thermal printers printhead contains multiple nozzles. The number of nozzles in the printhead has a significant impact on the print speed.

You can check “what is a printhead on a printer” to get a better idea about printheads.

Memory

The memory unit of thermal printers supports the microcontroller while processing data and running programs. Usually, advanced direct and thermal transfer printers have SDRAM or DRAM for these services.

Control Unit

The other name of the control unit is the microcontroller unit (MCU). It controls electric coils and nozzles to ensure hassle-free printing. Besides, it stores graphics, dot matrix characters, etc.

These are the basic parts of thermal printers. Except for these, you can find a display unit, an LED indicator, spindle, Label cutter, etc.

How Does a Thermal Printer work?

The operating principle of thermal transfer and direct thermal printers are straightforward. The entire printing process has four segments.

First, the thermal head produces heat until it creates an image on the thermal paper. There is no need for ink because of this thermal head with a couple of metal plates.

Then, the heat-sensitive films get wound around the transfer roller before the wrap on the platen roller.

After getting a print command, this platen roller moves forward to press the thermal head. In the end, gears ensure you have smooth continuity of each step. You can watch this video to know more about this topic: https://youtu.be/C0CkSRwRPXA.

How Do You Compare Direct Thermal And Thermal Transfer Printers?

If you notice sincerely, you can find some differentiating issues between the two types of thermal printers. You need to consider the following properties while comparing two high-class thermal printers of the present world.

Longevity Of Thermal Printhead

The printhead is a vital part of the thermal printer’s mechanism. In the case of thermal transfer printers, you can find thermal ribbons between the printer label and printhead. These ribbons provide excellent protection to thermal printheads to save them from friction and static problems.

On the contrary, printheads of direct thermal printers get connected to the label materials. This feature increases the chance of friction. That’s why thermal transfer printers usually last for an extended period compared to their competitive thermal printers.

Printer Configuration

Thermal transfer printers have a little bit of a complicated configuration. These printers consist of additional thermal ribbons to prevent friction. Thermal transfer printers have specific hardware To control and drive these ribbons.

Conversely, direct thermal printers offer a simple construction compared to a thermal transfer printer. You can easily set up these printers for high-volume printing.

Choice Of Media

The media choice is also an essential factor when you are looking for a reliable thermal printer. In the case of direct thermal printers, the media acts as a grinding material. It requires a lot of replacement due to its departure from printheads.

There are no such issues in thermal transfer printers. That’s why you can minimize the replacement cost in this case.

Requirements For Label’s Shelf Life

What is your required lifespan of a thermal printer label? This feature significantly impacts your choice between two types of thermal printers. Direct thermal printer’s label doesn’t provide high durability in extreme environments like thermal transfer printers.

That means you should go for thermal transfer printers if you require a long shelf life of labels. But both of these printers are suitable for labels having a short lifespan.

Cost-performance

You can’t say a one-line answer about the cost performance of thermal printers. It depends on multiple factors.

The longevity of printheads affects the cost performance of two types of thermal printers. Direct thermal printers require more replacement or repair compared to a thermal transfer printer. That means your printing cost increases for a particular volume of thermal printing.

Again, thermal transfer printers cost more due to their heavy maintenance. But the choice of printing media favors these types of printers to a large extent.

So, how can you optimize the printing cost?

You need to make a balance concerning the factors that affect cost.

Reusability

Thermal transfer printers support the reuse of thermal films. But direct thermal printers don’t deliver this feature.

Environmental Issues

Most electronic industries prefer green technology nowadays. Thermal ribbons are compatible with a crude oil-reinforced career. This material is not supportive of a green environment.

Direct thermal printers are the best if you intend to establish an eco-friendly atmosphere during thermal printing. These printers are free from thermal ribbons. So, you can fulfill the demands for pollution-free printing.

Now, it’s your choice. You have to consider these factors mentioned above to make the right decision.

Thermal Printer Advantages And Disadvantages

You need to have a clear idea about the advantages and disadvantages of thermal printers.

Advantages

- Cost-effective printing because of no use of ink.

- Easy maintenance.

- Portable

- Ecologically effective

- High printing speed with excellent resolution.

- Noise-free operation.

- Compatibility with both “heat” (Direct thermal printers) and “no heat” (thermal transfer printers) operations.

- Minimum power consumption.

Disadvantages

- Direct thermal printers have compatibility with a single color at a time.

- Thermal Label printings get fade within time in some cases.

- Lacks quality in high heat conditions.

What Are Thermal Printers Used For

What two types of thermal printer exist really matters because of their reliable applications. These printers have superb use in the following industries-

Medical Industry

You can use thermal printers to print the patient’s ID card, labels for research works, etc. Besides, asset analysis papers are also thermally-printed in most cases.

Product Manufacturing

Thermal transfer printers are effective for label printing in product manufacturing. These printers have great use in barcodes, part management, maintenance, ticketing, development reports, color photos, etc.

Retail

POS, price tags, inventory, office mugs, and ID cards are applicable for retail and hospitality departments. Direct and transfer printers are appropriate for these types of label printings.

Shipping

Transport and logistic sectors. Like shipment, receipt, inventory, etc.

Government Sector

Administrative works, supply chain, identification cards, etc.

Thermal Printers In Color Printing

Are you looking for a thermal printer for color printing?

It’s OK. Thermal transfer printers offer color printing with excellent reliability. You need to use thermal ribbons to get color in this case.

The notable part is you can only get a single color on printed papers. The color completely relies on the ribbon type.

So, how do you select thermal ribbons for color printing?

It depends on several factors. The most significant issues are-

Types Of Ribbons

Resin Ribbons

- Costly

- Highly durable

- Compatible with printing on polyimide, polyester, etc.

Resin And Wax Ribbons

- Tolerant to chemical contaminants to a certain extent.

- Comparatively less expensive

- Effective for layered papers and labels.

Wax Ribbons

- Cheap

- Vulnerable to external contaminants

- Suitable for pricing and shipping labels

Width Of Ribbons

Remember, the ribbon width should be greater than the label width. Otherwise, the printhead can face corrosion.

Role Dimensions

You need to check the threshold dimensions (Roll length, core size, etc.) of rolls while choosing thermal ribbons. You can follow the manufacturer’s guidelines in this case.

Ink Types

Thermal ribbons have compatibility with different ink types. That’s why you should select ribbons that suit the ink configuration of your printer.

Direct thermal printers offer only black and white printing. But how can you print with multiple colors?

Some worthwhile thermal printers provide full-color thermal printing. Such as

- Zink thermal printers

- Zebra IQ thermal printers

- Dye-sublimation printers

- Retransfer thermal printers

Warnings

- Never take off the hot printed papers.

- Don’t make contact with the thermal head when printing runs.

- Never try to use a thermal film again in direct thermal printers.

FAQs

- What Is Thermal Printing?

Thermal printing is a unique type of printing technology. Here, printheads provide controlled heat to print on thermal papers.

- Is A Zebra Printer A Thermal Printer?

Yes. Zebra printers are found in both direct thermal and thermal transfer forms. Some particular types of Zebra printers support thermal printing.

- What Is The Difference Between Thermal And Inkjet Printers?

Thermal printers use heat alternatives to ink. But inkjet printers operate through ink controlled by the printhead.

Thermal printing is quicker than inkjet printing.

The thermal process is dry, while the inkjet printing process is wet due to the use of ink.

- What Type Of Printer Is A Thermal Printer?

A thermal printer is a dot-matrix printer by nature. It prints the images and texts on thermal-sensitive films.

- What Thermal Printer Features Matter Most?

The most necessary features of thermal printers include print speed, resolution, lifespan, cost, and color.

- How Long Does A Thermal Printer Last?

The average lifespan of a thermal printer is around 8-10 years. Then, you may need to change the printhead and continue printing.

- What Are The Types Of Thermal Paper Used In Thermal Printing?

Infrared and visible light thermal papers are the most-used papers for thermal printing.

Conclusion

This is everything you need to know about “what two types of thermal printers exist.” We intended to explain all the details in simple words. We hope it will be beneficial for you. Stay tuned to get more trustworthy information about various printers.

Happy printing.