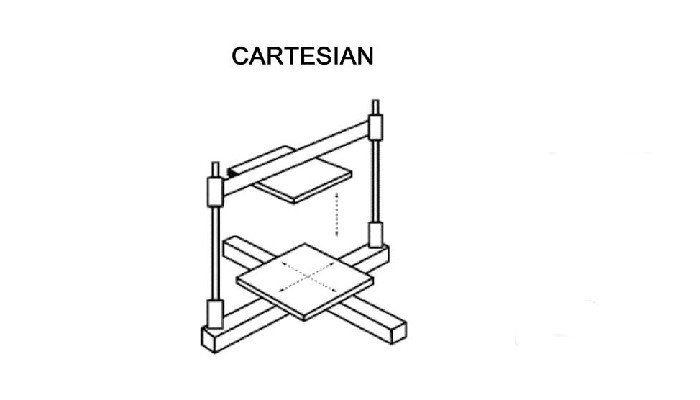

Cartesian printers get their name from the Cartesian combine system, which plots points using X, Y, and Z collaborates. The position of the paper feed and the extrusion is determined using this co – ordinates.

Cartesian printers accomplish this by using a network of tracks to adjust the print head with print surface, allowing the extrusion to be positioned anyplace.

Ink containers are housed in the printhead, which is an element of a printing. It’s usually found underneath the printer’s lid and just might be blocked with inks throughout age.

- The Benefits of Cartesian Printer

- The Drawbacks Of Cartesian Printer

- How Does It Function?

- What Distinguishes Them?

- Cartesian Printers Are Exemplified By The Following

- Delta Printer

- The Benefits of Delta Printer

- The Drawbacks Of Delta Printer

- Delta Printers Are Exemplified By The Following

- How Does It Function?

- What Distinguishes Them?

- What Sets Delta Printers Apart From The Competition

- Biggest Delta Printer

- Best Delta Printer In 2022

- Cartesian vs Delta Printer: Things That Are Different

- Cartesian Vs Delta Printer- Which Printer Can Possibly Print Quicker And Why?

- Cartesian Vs Delta Printer- Which Of These Is Preferable For Jobs That Require A High Level Of Standards And Quality?

- FAQ

- Conclusion

The Benefits of Cartesian Printer

Huge Network And Widespread Acceptance

The acceptance of Cartesian printers as well as the large group from which to pull may be the most significant benefit.

The key factors for such printers’ effectiveness include their widespread fame, that enables them to be extremely convenient, appear completely constructed at the doorway, have excellent customer service, and a large following to interact with.

Accuracy And Thoroughness

This quality is unquestionably at the top of the list, because in publishing, details are everything. Cartesian printers, luckily, get a system which aims to facilitate a deep impact despite printing every line with speed and precision.

They provide excellent printability. Patterns are noted for having a nice surface and distinct outlines, although both are desirable qualities in today’s modern printer.

Supply of Components

Additional benefit of Cartesian printers’ great appeal is the copious accessibility of spares, equally affordable and costly, depending on the situation.

There is a vast marketplace available on the internet that’s eager for someone like you to buy a Cartesian printer, and it’s typically giving fantastic prices and discounts.

Excellent Printing Performance

You can start printing various substances with a competent Cartesian printer, particularly composite options like TPU, TPE, and soft PLA.

You may quickly adjust a Cartesian printer to a Main Drive configuration to benefit from the advantages of producing in order to get the exact both precisely and quickly.

Huge Group And Widespread Acceptance

The most significant benefit to having a Cartesian printing machine is its widespread use and large group of users.

The Drawbacks Of Cartesian Printer

Limited Speed

Cartesian printers’ printheads are huge and weighty, so they put up impulse as they drive forward to create the printed patterns. It’s only natural to assume that it won’t be able to shift conduct quickly and operate at a high speed while performing so.

Rather, this would damage the printouts, as you can’t expect to pause and rotate fast if you’re moving fast. This is among the limitations of a Cartesian printer, and it’s easy to follow up why, distinct from its competitor, which is not designed for efficiency.

Weighty Printer

That’s also related to efficiency, since the gradual increase restricts the number of quick motions that can be done without compromising printability. You’ll see buzzing in the print once you’ve reached a sufficiently fast speed.

There’s many ways to make it lighter, but because of the device’s structure. The extra bulk is attributed to the reason that the printing bed rotates as well. Due to the obvious motion, some have complained about poor printability while using a hefty solid building plate.

How Does It Function?

To set the printing head and publish in a 3-proportion area, Cartesian printers operate elements linear through the X, Y, and Z axes. A printing head is usually moved through the Z-axis by an X or Y crane, while alternative motions are ultimately dependent on the printers.

What Distinguishes Them?

Cartesian printers, on the other hand, are separate from printers that reveal the difference control points, like polar. Polar printers employ guidance and control grids, where Cartesian printers utilize collaboration to figure out how to publish.

Cartesian Printers Are Exemplified By The Following

- Ender 3

- Prusa i3

- MakerBot Replicator

- Voxellab Aquila

- Advanced Creality Ender 5 Pro

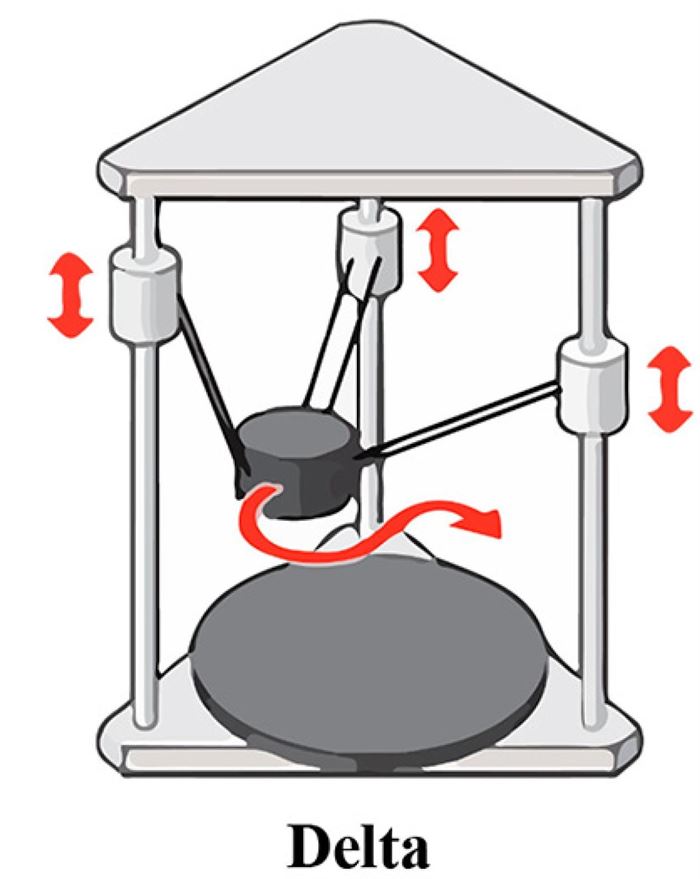

Delta Printer

A Delta printer is built for rapid publishing, which it definitely accomplished, however the printing performance is sacrificed to some level, because final printing quality may not be as

flawless as a conventional gradual Cartesian printer. The printer, on the other hand, has a noticeable benefit in terms of efficient vertical print, and the publishing heights are generally not as restricted as it is with Cartesian printers.

The Benefits of Delta Printer

Quick And Effective

Delta printers are often regarded as among the quickest printers available. They are familiar for producing prints in a timely and high-quality manner. Delta printers get their pace due to 3 pace control that each runs one of the 3 parallel arms separately.

Ideal For Making Large Prints

The printing surface on the Delta printer could be tiny, but it doesn’t imply it’s useless. To make up for the absence of substantial size, the creators encouraged individuals to think about things differently.

Printing Bed

It has three members which can rotate the beak in all angles and circle printing beds. This provides you with extra printing surface as well as more creative patterns to create.

Time

This printer is, undoubtedly, considerably quicker than a Cartesian printer. Both of these are quicker than constructing any item, but Delta has the stronger position in this regard.

Distance

This printer can reproduce significantly higher or thinner things than a cartesian because of its limbs and length. Users have more flexibility across an item’s height.

Shifting Weight Is Lighter

This benefit is the fact that it is faster than a Cartesian printer. Because there is less movable heaviness, users can make faster movements with either lethargy or noises compromising printability.

In comparison towards the outsides of the printing platform, this even results in increased consistency in the center.

It’s Simple To Update And Manage

Although repairing can be challenging, updating and servicing a Delta printing technology is generally straightforward and does not require substantial understanding of your printer.

The Drawbacks Of Delta Printer

Momentum

Objects might not even turn out as precisely as we desire because of the printer’s quickness. There’ll be occasions when we will need to produce the thing repeatedly to get it just right. Accuracy suffers as a result of faster functionality.

Cube

This may not be the device for you if you’re an engineer attempting to create a cube structure design. This can construct a cube, but never with precision. Cubic throughout is quite weird because of the building’s curves.

Accuracy And Intricacy Aren’t Up To Standard

The Delta printer isn’t perfect. This could offer unrivaled pace and mechanization, however quality and intricacy may be sacrificed.

Bowden Displacement Configuration Restrictions

The Bowden-style displacement is fantastic in theory, reducing superfluous burden from the printer and letting it produce more quickly, but it comes with several drawbacks.

Compact Manufacturing Structure

The characterizing is round, so that you can definitely design a structure on it, however the capacity is restricted, which is something to keep in mind.

Compact Group

One More significant disadvantage to consider is the Delta-style printer’s growing, presently tiny place, which lacks the same amount of service, guidance, and interaction as the Cartesian group.

Troubleshooting Is More Difficult

The mechanisms of a Delta printing machine are slightly more complicated than those of a Cartesian machine because the triple arms travel in a quadrilateral and discharge while shifting angle.

Delta Printers Are Exemplified By The Following

- TEVO Little Monster

- Monoprice Mini Delta

- FLSUN QQ-S-PRO

- RepRap Morgan

- RepRap Helios

How Does It Function?

Delta printers have 3 arms that are connected to upright tracks. The printer is hinged towards the ends of every arm, and the arms operate with each other to alter the location of the printer. The printhead’s position (Z axis) and placement (X- and Y-axes) related to the printing platform are controlled by the rhythmic movements of a delta printer’s arm.

What Distinguishes Them?

Because the motion of the paper feed is managed by arm instead of defined axes, Delta machines differ technically from standard Cartesian printers. Delta printers are also distinctive among the various forms of FDM printers for this purpose.

The functional reference frame, on the other hand, is identical to that of other Cartesian printers.

What Sets Delta Printers Apart From The Competition

Delta and Cartesian styles are two different ways of looking at things. The extrusion, bed, and actuators are all present in Printing machine; however, they are ordered and situated separately.

As a result, it’s impossible to verify whether a printing machine was generated with a delta printing machine or not. The Delta printing machine is using the same thread as delta printing, including PLA, ABS, flexibles, and other unusual threads.

This is where the resemblances stop.

Biggest Delta Printer

The C3Dt/bd is the biggest delta printer you have seen before, and it’s fully customized and accessible. It is approximately 1.5 m (5.5 feet) tall with a construction capacity of 280 mm (12.5 inches) in diameter by 1380 mm (47.8 inches) in depth.

Best Delta Printer In 2022

Some of best delta printer of 2022 are given below-

| Name | Maximum Building Volume of (mm) | Momentum |

| Monoprice Mini Delta | Approximately 95 x 100 x 110 | Up to 120 mm/s |

| FLSUN Q5 | Approximately 150 x 180 x 140 | Up to 100-250 mm/s |

| He3D K280 Delta | Approximately 250 x 240 x 550 | Up to 110 mm/s |

| FLSUN QQ-S | Approximately 245 x 240 x 320 | Up to 260 mm/s |

| Frankensbox FX-800 | Approximately 100 x 120 x 150 | Up to 100 mm/s |

| Monoprice Delta Pro | Approximately 250 x 220 x 250 | Up to 110 mm/s |

| WASP Delta 2040 PRO Turbo | Approximately 150 x 180 x 350 | Up to 450-550 mm/s |

Cartesian vs Delta Printer: Things That Are Different

| Comparison Factors | Cartesian Printers | Delta Printers |

| Weight | Hard | Easy |

| Cost | Amazon | Amazon |

| Speed | Slow | Fast |

| Update and repair | Simple | Difficult |

| Print Limit | Print size restrictions | High images are usually possible. |

| Community | High | Low |

| Movement | Cartesian printing machines are capable of moving between left to right, forepart to backward, and top to bottom | It changes the positions of such quadrilaterals to go from one X or Y spot to the next. |

| Print Bed | A cubic, movable print bed is standard in Cartesian printing machines. | The print bed on a Delta printer is typically round. |

Cartesian Vs Delta Printer- Which Printer Can Possibly Print Quicker And Why?

As they are clearly intended for it, Delta printing machine leads the publishing pace rankings. The heaviness of the working components has been lowered, allowing the delta signals to travel more smoothly and fluently.

These 3 components that travel upwards on a rail network also help to keep the printing head stable.

This, on the other hand, implies that such printers may encounter troubles more frequently than a Cartesian printing machine, and therefore getting higher printability will be way more difficult.

Cartesian Vs Delta Printer- Which Of These Is Preferable For Jobs That Require A High Level Of Standards And Quality?

Accuracy and clarity are enhanced with Cartesian printers. They can print excellent clarity and perfection, however the procedure is noticeably weaker than with Delta printers.

Comparing Delta and Cartesian printers, Cartesian printers produce higher-quality, sleeker textures. Undoubtedly, the printer specifications play a role, but we assume that all print characteristics have already been set appropriately.

In 3D printing, accuracy is everything, and Cartesian printing doesn’t skimp on it, which is why they’re so famous and have such a large user base. The focus is to enhance printability and appearance on a continuous basis.

By combining a greater extrusion and hotend with perfectly alright Cartesian printers, you may improve the printability.

FAQ

- Is A Delta Printer Better?

Delta printers contain circle printing beds that make better use of the printed surface, particularly while making circle patterns. Delta printers also can make longer things than typical Cartesian machines due to their design. The pace of a Delta printer is one of its key features.

- What Is A Cartesian Printer?

Cartesian printers are able to motion from left to right, and forward to backward, and upwards and downwards. Simply described, it travels from point A to point B by shifting each side at a moment. A cube, rotating printing bed is common in Cartesian printers.

In certain circumstances, the printing bed travels towards the nozzles rather than the nozzles moving towards the printing surface.

- Do Delta Printers Print Faster?

They may produce at speeds of up to 250 mm/s, which is extremely fast for a 3D printer. Those greatly admired machinery strive to offer outstanding quality with adequate specifics while retaining such a fast pace.

Delta-style machines, which are designed for high-volume printing, are unlikely to fall out of favor for an extended period of time. They are designed for folks with a fast turn-around time and corporations that require such reliability.

As a result, it’s as if these machines were designed to accommodate this level of difficulty and intricacy. It’s one of several key advantages, and it’s difficult to ignore while purchasing a 3d printing machine.

Furthermore, the majority of these use the Bowden extruder configuration, which removes the excess weight from the printer, keeping it lighter and resistant to shocks during abrupt specific movements.

- What Is A Delta Print?

The Delta printing machine includes large engines and extractors mounted on the upper section for quick production. Because the printing machine must maintain excellent precision at a fast pace, the toolhead is kept lightweight and minimal. A delta printing bed is normally round rather than rectangular, and it never moves.

Conclusion

When you choose a trusted company, each of these machines will meet or surpass your requirements. Users won’t be disappointed with any option, but this will vary on how much effort you would like to spend on the printer’s assembly.

Cartesian printing machines are usually able to publish straight away. Everything has been put together. Everything you must do is tell it what to do. You’ll get everything that you need with such a delta printing, but you’ll have to put it together yourself.

If you’re in a hurry, a conventional Cartesian printing is the way to go. Purchase a Delta unless you want to learn how it operates and assemble it yourselves.