So, we’re talking about resin printers, huh? These little machines are like wizards of the printing world. They can create some seriously mind-blowing stuff. And the best part? You don’t have to be a skilled wizard to use one!

Now, I know what you’re thinking. “But how does it work?” Well, my friend, that’s what we’re here to find out. And let me tell you; it’s not as complicated as it seems. In fact, I’m pretty sure my grandma could figure it out (no offense, Grandma).

But first, let’s talk about why resin printing is so fantastic. The level of detail and quality you can achieve with these bad boys is insane. Like, “I can’t believe it’s not butter” levels of insane. And the applications are endless! From jewelry making to rapid manufacturing, resin printing is changing the game.

So, get comfy, and let’s dive in. We’re about to explore the ins and outs of how does a resin printer work. It will be a wild ride, but I promise to hold your hand through it all. Just don’t blame me if you become addicted to resin printing and start churning out miniatures like there’s no tomorrow.

- Understanding Resin Printing

- Components of a Resin Printer

- How Does Resin Printing Work?

- Types of Resins Used in Resin Printing

- How to Choose a Resin Printer

- Tips for Successful Resin Printing

- Common Resin Printing Problems and Solutions

- Comparing Resin Printing to Other Printing Technologies

- FAQs

- Conclusion

Understanding Resin Printing

First, let’s talk about what resin printing is. Basically, it’s a type of 3D printing that uses liquid resin to create objects. You know those fancy sculptures you see in museums? Well, you can make your mini versions with a resin printer!

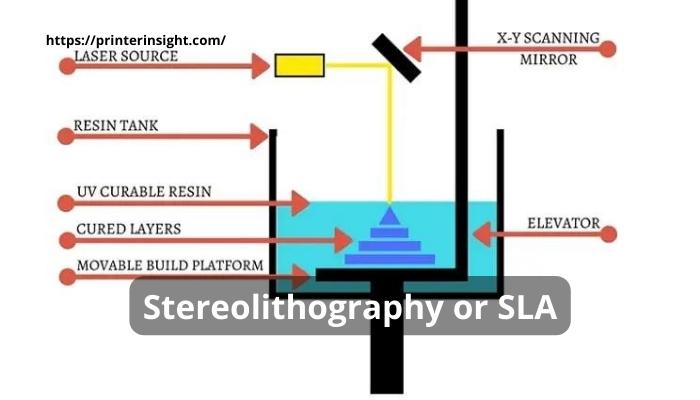

Now, there are a couple of different types of resin printers out there. Some use digital light processing (DLP) technology, which cures the resin using a projector. Others use stereolithography (SLA), a laser, to cure the resin. But don’t worry, we’ll get into the specifics later.

One of the significant benefits of resin printing is the level of detail you can achieve. I’m talking about super intricate details that will make your friends say, “Wow, how did you make that?!” Plus, resin prints come out with a smooth finish that’s just asking to be caressed.

And it’s not just small objects you can print, either. You can make anything from jewelry to figurines to custom orthodontic models. The sky’s the limit! Resin prints also have a higher resolution than filament prints, so you’ll end up with a more accurate final product.

And let’s not forget about the fun factor. Watching your creation come to life layer by layer is like watching a tiny little miracle unfold. It’s mesmerizing. So, if you’re looking to take your 3D printing game to the next level, resin printing might be your new favorite hobby.

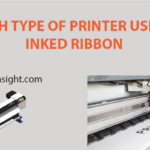

Components of a Resin Printer

Ah, let’s talk about the components of a resin printer. These bad boys are made up of a few key parts that work together to create your masterpiece.

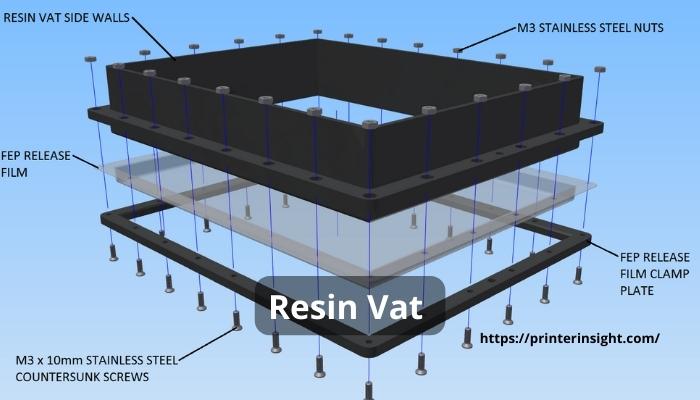

- 01.Resin Vat

First up, we’ve got the resin vat. This is where the liquid resin is stored before it’s printed. Think of it like a little swimming pool for your resin.

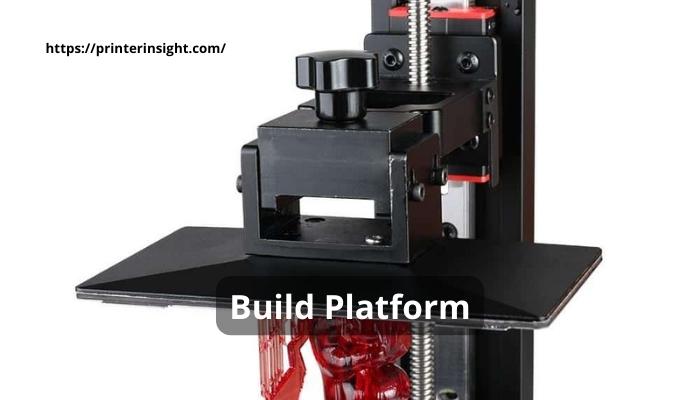

- 02.Build Platform

Next, we’ve got the build platform. This is where the magic happens! The build platform moves up and down as each resin layer is printed, slowly building your creation layer by layer. It’s like watching a tiny elevator in action.

- 03.Light Source

Of course, we can’t forget about the light source. This is what cures the resin and brings your creation to life. Without the light source, your print would be a sad puddle of liquid resin.

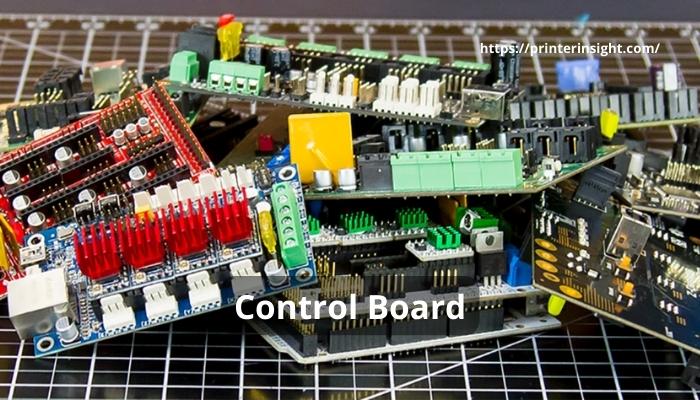

- 04.Control Board

And then we’ve got the control board. This is like the brain of the operation. It tells the printer what to do and when to do it. It’s the conductor of this tiny little orchestra.

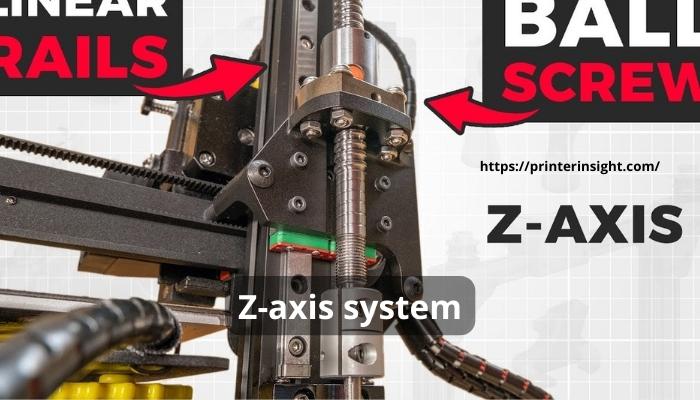

- 05.Z-axis system

Finally, we’ve got the Z-axis system. This is what controls the height of the build platform as each layer is printed. It’s like a tiny little robot arm that moves the platform up and down.

So, there you have it! The components of a resin printer. Without these key pieces, you’d just have a bunch of resin sitting in a vat doing nothing. But with them, you can create some seriously cool stuff.

How Does Resin Printing Work?

The million-dollar question: how does resin printing actually work? It’s surprisingly simple, my friend.

- First, the printer lays down a thin layer of liquid resin on the build platform. Think of it like pouring syrup on a pancake.

- Then, the light source (either a laser or a projector) cures the resin, essentially turning it from liquid to solid. It’s like a tiny little miracle happening right before your eyes.

- The build platform then moves down a tiny bit, and the printer lays down another layer of resin on top of the first layer. And the light source cures that layer, too. Rinse and repeat until you’ve got yourself a completed print!

- Now, when it comes to resin selection, that’s where things get a little more complicated. Different resins have different curing times and properties, so choosing the right one for your project is essential. But we’ll get into that later.

So there you have it, folks! That’s the basic process of resin printing. It’s like watching a tiny little construction worker build something out of Legos, layer by layer, except, you know, way cooler.

Types of Resins Used in Resin Printing

Time to talk about the types of resins used in resin printing. This is where things get interesting.

- 01.Standard Resins

First up, we’ve got standard resins. These are your basic, run-of-the-mill resins that come in various colors and properties. They’re great for printing larger objects, as they have a longer curing time.

- 02.Flexible Resins

Next, we’ve got flexible resins. As the name suggests, these resins are more flexible than standard resins. They’re excellent for printing objects like phone cases or toys that need a little bit of give.

- 03.High-detail Resins

Then there are high-detail resins. These are the resins you want if you want to create something with incredibly intricate details. They have a faster curing time so you can print more layers in less time.

- 04.Specialty Resins

And let’s not forget about specialty resins. These resins are tailored to specific applications, like dental or jewelry printing. They often have unique properties ideal for these specific use cases.

How to Choose a Resin Printer

Now, when it comes to choosing a resin, there are a few things to consider.

- First, you want to view the properties you need for your project. Do you need flexibility? High detail? A specific color?

- You’ll also want to consider the curing time. Some resins cure faster than others, which means you can print more layers in less time. But faster curing times often mean sacrificing some level of detail.

- And finally, you’ll want to think about the cost. Different resins come at different price points, so you’ll want to find one that fits your budget.

Tips for Successful Resin Printing

Another age-old question arises: how do I make a successful resin print? Fear not, my friend. I’ve got some tips for you.

- First and foremost, make sure your build platform is level. This is like the foundation of a house. If it’s not level, your print is going to be wonky.

- Next, keep an eye on your resin levels. You don’t want to run out of resin mid-print. Trust me; it’s not a good time.

- And speaking of resin, make sure you’re using the right resin type for your project. Using the wrong resin can result in a failed print or a print that doesn’t come out quite right.

- When it comes to curing your print, follow the manufacturer’s instructions to a T. Different resins have different curing times and methods, so it’s essential to follow the instructions closely.

- And finally, be patient. Resin printing takes time, especially if you’re printing something with many layers or intricate details. Don’t rush it, or you’ll have a subpar print.

There we go! Some tips for successful resin printing. Follow these, and you’ll be a resin printing pro in no time.

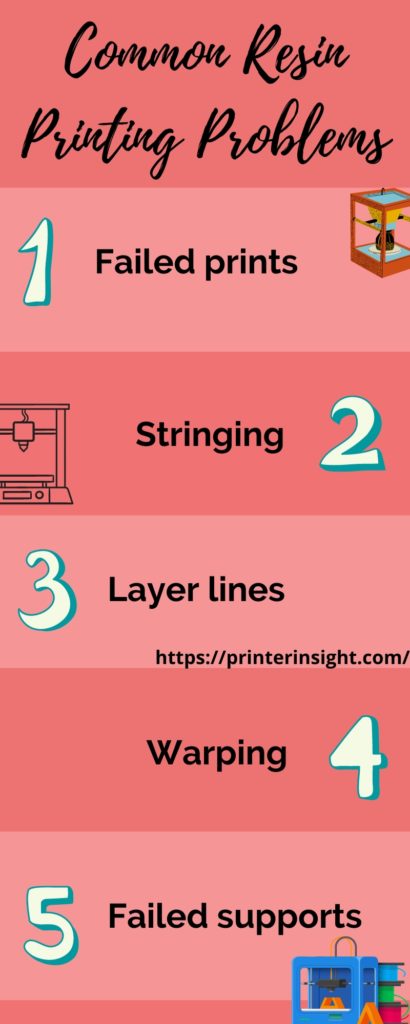

Common Resin Printing Problems and Solutions

The joys of 3D printing are unmatched. As much as we love it, it’s not always rainbows and unicorns. Sometimes, things go wrong. But fear not, my friend! I’ve got some solutions to common resin printing problems.

Problem #1: Failed prints

This is when your print either doesn’t stick to the build platform or comes off midway through the print.

Failed prints can be caused by a variety of factors. One of the most common causes is an uneven build platform. If the platform isn’t level, the resin won’t adhere properly, and the print will fail.

Another factor can be an inadequate or poorly performing build plate. The resin must stick well to the build plate to create a stable print.

- Solution

Failed prints are like a bad date – nobody wants them. To prevent this disaster, you need to ensure your build platform is level and that you’re using a build plate that’s as sticky as a Kardashian’s Instagram.

You can also adjust your printer settings to ensure your object is properly supported – like how a sound support system keeps you going through tough times.

Just ensure that the printing process isn’t interrupted; otherwise, it’s like getting ghosted by your printer.

Problem #2: Stringing

This is when little strings of resin end up connecting different parts of your print.

Stringing is like a bad hair day for your prints. This happens when little strings of resin end up connecting different parts of your print. It’s caused by resin that’s too hot and runny, or print that’s over-cured and brittle.

It’s like Goldilocks and the Three Bears – you want the resin temperature and curing settings to be just right. Not too hot, not too cold, but just right. That way, you’ll have a smooth and string-free finish.

- Solution

Stringing is like those annoying little hairs that stick to everything after a haircut. To avoid this, make sure your resin isn’t too hot and that you’re using the proper curing settings – like how a hot date needs to be just the right temperature. You can also try adjusting the retraction settings on your printer, which is like wiping away those little hairs so they don’t ruin your perfect finish.

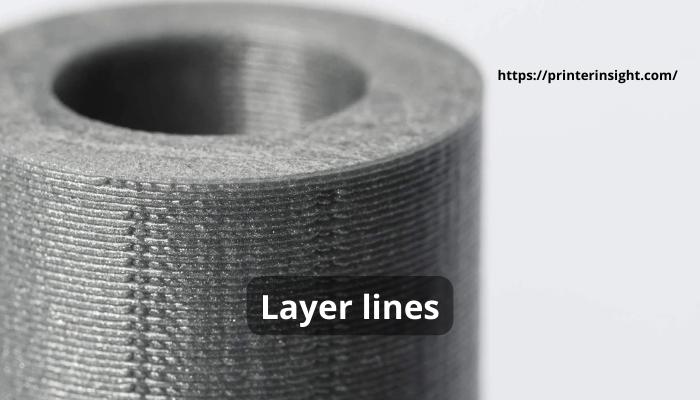

Problem #3: Layer lines

This is when you can see the individual layers of your print instead of a smooth finish.

Layer lines are the bane of every resin printer’s existence. It’s like a constant reminder that you’re not a master craftsman…yet. The problem is caused by inadequate bonding between the different layers of your print. This can be caused by various factors, like wrong exposure times or layer height, or simply insufficient curing.

It’s like when you don’t put enough frosting between layers of a cake – you end up with a less-than-stellar end product.

- Solution

Layer lines are like those unwanted wrinkles that pop up out of nowhere. To prevent this, ensure your layers are bonding properly by adjusting your exposure time or layer height – like how a good skincare routine keeps those wrinkles at bay.

If those lines still persist, don’t worry – you can always use post-processing techniques like sanding or polishing to smooth things out. It’s like giving your print a little facelift without any needles involved.

Problem #4: Warping

This is when your print warps or curls during the printing process.

I like to call warping the nemesis of resin printing. It’s like trying to straighten your hair on a rainy day – a losing battle. Warping occurs when the print cools too quickly, causing it to warp or curl as a bad ’80s perm.

- Solution

Warping is like trying to keep your cool during a heatwave – sometimes, it’s just impossible. To keep your prints nice and flat, make sure your build platform is as level as a balance beam, and consider using a heated build plate – kind of like a hot stone massage to keep things relaxed.

If that’s not enough, try printing in a warmer environment or adjusting your print settings to reduce the cooling rate – it’s like chilling out in a cabana instead of sweating it out in a sauna.

So, don’t let warping ruin your perfect prints – keep things level and cozy for a successful outcome.

Problem #5: Failed supports

This is when the supports you’ve printed for your object don’t hold up during the printing process.

It’s like trying to build a house of cards with paper clips. If your support structures aren’t strong enough or positioned correctly, your object will collapse like a failed souffle.

- Solution

Avoiding failed supports is like trying to build a house of cards without the wind blowing it away. To ensure a solid foundation, make sure your support structures are as thick as a Snickers bar and in the right positions – kind of like building a Lego house without missing pieces.

If you’re still struggling, specialized support generation software can be like calling in the Avengers to help with the heavy lifting.

So, don’t let your supports crumble like a cookie – get them strong and reliable for a successful print.

And there you have it! Some solutions to common resin printing problems. Don’t let these little hiccups discourage you. With some troubleshooting, you’ll be back to printing perfect objects in no time.

Comparing Resin Printing to Other Printing Technologies

It’s always fun to learn something new, isn’t it? Now, we’ll be talking about resin printing and how it compares to other printing technologies. Don’t worry, we won’t get too technical. Think of me as your trusty guide on this journey. Ready? Let’s go!

- Let’s start with the basics. Resin printing, also known as stereolithography or SLA, is a type of 3D printing technology that uses photopolymer resin to create objects layer by layer. It’s like a fancy, high-tech glue gun. And who doesn’t love glue guns?

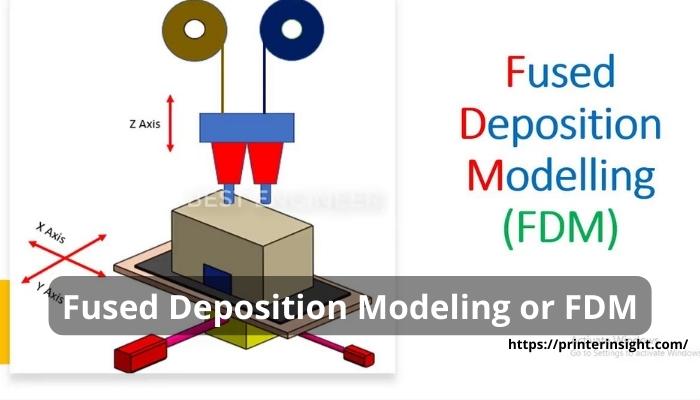

- Now, how does resin printing compare to other printing technologies? First up, we have Fused Deposition Modeling or FDM. This is like the basic printer of the 3D printing world. It uses plastic filament to create objects but is not as precise or detailed as resin printing. It’s like comparing a paint roller to a fine-tipped brush. You can do more with the brush, but sometimes you just need to cover a large area quickly.

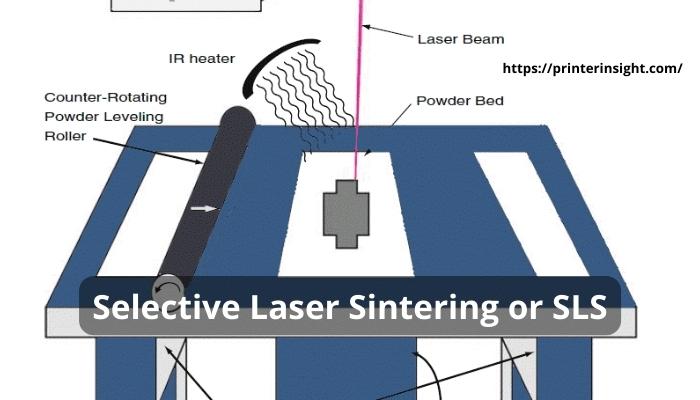

- Next, we have Selective Laser Sintering or SLS. This technology uses lasers to melt and fuse powdered materials into objects. It’s like playing with sand, but on a microscopic level. SLS can create more durable things than resin printing, but it’s also more expensive. It’s like the fancy sports car of printing technologies.

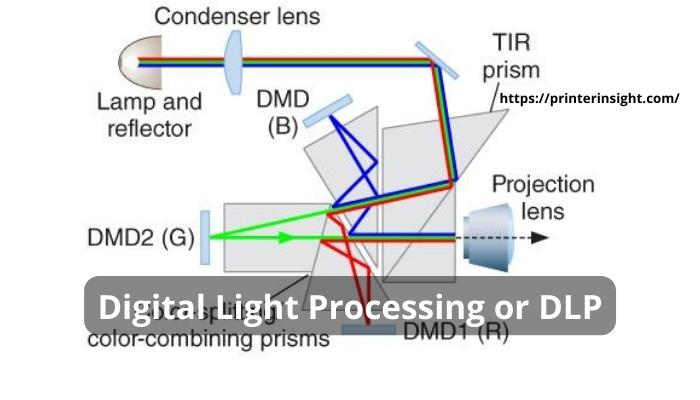

- Finally, we have Digital Light Processing or DLP. This is similar to resin printing, but it uses a projector to create the layers instead of a laser. It’s like a mini-movie projector, but you’re creating a 3D object instead of watching a movie. DLP is faster than resin printing, but it’s not as precise.

So, there you have it. Resin printing may not be the only printing technology, but it’s definitely a contender. It’s like the Swiss Army knife of printing technologies – versatile, precise, and sometimes a little bit fancy. And who doesn’t love a good Swiss Army knife?

FAQs

What types of objects can be printed using resin printers?

Resin printers can bring your wildest 3D printing dreams to life! They’re perfect for creating detailed figurines, jewelry, and many delicate items. Plus, they’re great for making prototypes and models that require high accuracy.

How long does it take to print an object using a resin printer?

Well, that depends on a few factors. The size and complexity of the object will affect the printing time, and resin printing is generally slower than other 3D printing technologies due to the need for curing time between layers. Good things come to those who wait, right?

Can resin printers print multiple colors?

Sorry, but most resin printers can only print in a single color at a time. If you’re looking to print in multiple colors, you may need to get creative and switch out resin tanks between prints.

How expensive is a resin printer?

Like most things in life, resin printers can vary in price from a few hundred bucks to several thousand dollars. While they may cost more than other printers, their level of detail and accuracy make them well worth the investment.

What kind of software is needed to operate a resin printer?

Don’t worry; you don’t need a Ph.D. in computer science to operate a resin printer. Most printers come with their software to prepare and slice 3D models before printing. But if you’re feeling adventurous, third-party software options are also available.

How long does the resin last?

The shelf life of resin can vary, but it typically lasts 6 to 12 months. Just like your favorite snack, store your resin in a cool, dry place away from sunlight to maximize its shelf life.

Can I recycle used resin?

Sadly, the resin isn’t as recyclable as your plastic water bottle. But don’t worry, there are ways to dispose of it safely without harming the environment. You can solidify it with a hardening agent or send it to a hazardous waste facility.

What kind of ventilation is needed for resin printing?

Resin printing can produce some funky fumes, so it’s important to print in a well-ventilated area or with a dedicated fume extractor. Or, you can rock a respirator like a boss.

Can resin printing be used for mass production?

While resin printing can produce high-quality objects with intricate details, it may not be the best option for mass production due to the slower printing speed and the need for curing time between layers. But hey, if you need a small batch of high-quality items, resin printing is your go-to!

Is it safe to use resin printers at home?

Resin printing can be safe at home when appropriately used with proper ventilation and safety measures. Remember to follow manufacturer guidelines and safety precautions to minimize potential risks. And don’t forget to have fun!

Conclusion

To summarize, resin printing is a technology that has transformed the world of 3D printing. Its ability to produce intricate and high-quality prints has opened up new possibilities for creative professionals in various fields.

While there are specific challenges to resin printing, such as the cost and messiness, the benefits can make it a worthwhile investment for those seeking to produce detailed and complex prints. Proper equipment, software, and safety measures are necessary for successful resin printing.

Overall, diving into resin printing can be a rewarding experience for hobbyists and professionals alike. Technology offers endless possibilities for creativity and innovation, and who knows what unique creations can be brought to life through this fascinating process?