Wondering how thermal transfer printers work? Trying to find how these thermal transfer printers print last for a long time? Then you are in the right place.

Thermal transfer printing is used everywhere in manufacturing, creating labels, barcodes, safety signs, bills, etc. Let’s get started to know the process of how a thermal transfer printer works.

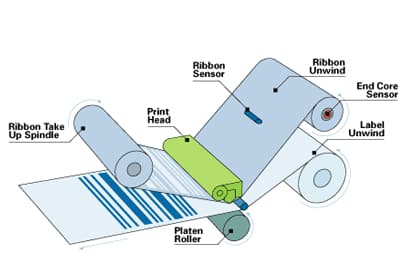

Key components in the thermal transfer printing process

There are three main components in a thermal transfer printer. They are

- Thermal printhead

- Ribbon

- Substrate

Thermal printhead

It is the most important component in a thermal transfer printer. It consists of a fixed number of dots inside. They can help in producing a sufficient amount of heat to transfer the black color to the material. Each dot is about 1 millimeter.

Thermal printheads come in multiple resolution options. Also providing more than sufficient charge can destroy thermal printheads. The name itself suggests it’s reactive to thermal energy.

Ribbon

The quality of the printing mostly depends on the ribbon that we use for printing. They do come in different kinds of materials like wax, resin, etc. You can select the color of the ribbon for your required color print.

The ribbon material must match and should be friendly with the label material for better quality. Also if the temperature of the thermal printhead is very high, it may burn the ribbon.

Substrate

The substrate is the component where you want to print. It need not be only a paper. It can be plastic, synthetics, or any kind of material.

How Does A Thermal Transfer Printer Work?

Thermal transfer printers have a wide range of features as compared to others. They are ideal options for long-term working projects. They also work very quickly. They do come with multiple sensors inside for the heating process and alarms.

A thermal transfer printer starts its work by heating. When the electric charge is acquired, the dots inside the thermal printhead will get heated. The microprocessors inside take care of the heating process.

The microprocessor also decides what are the pins that need to be heated. These pins are resistive and designed to access a sufficient amount of charge. The heated pins in the thermal printhead start acting on the ribbon.

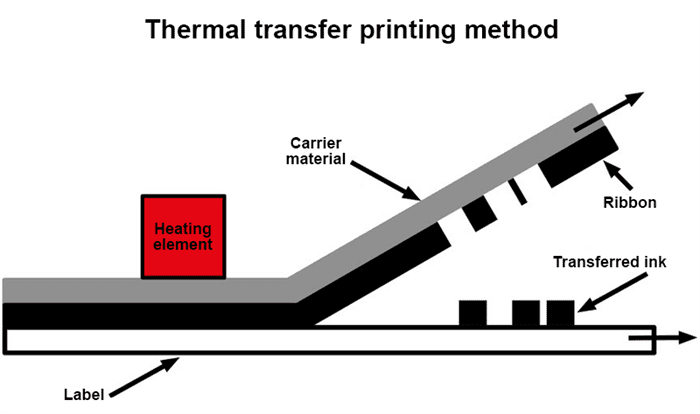

The ribbons are made of different materials and are placed perfectly fitted inside a printer. When the ribbon gets heated, it tends to move from solid format to liquid format. The melted ribbon will fall on the label inside the printer. The label starts absorbing the melted ribbon and formats into ink.

The label material and the ribbon material should match each other to provide maximum durability. The ink acquired by the label due to the heating of the ribbon can be used now.

It will now print the high-resolution images and words with maximum quality and durability. When a particular dot is turned off, meaning it won’t print in that area, the ink from the ribbon will not be provided.

FAQ

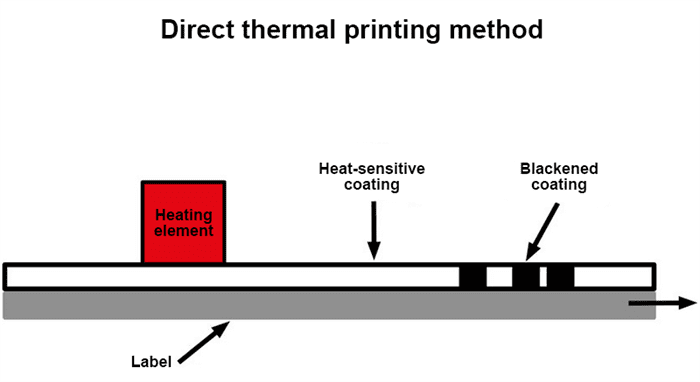

What is the difference between direct thermal printing and thermal transfer printing?

The name itself suggests that both use thermal energy for printing. The main difference between them is using a ribbon in thermal transfer printing. In direct thermal printing, the label consists of a coating for heat energy.

The thermal printhead directly applies the heat to the label. However, there are flexible thermal transfer printers too. They can print without using any ribbon or toners like direct thermal printers.

When the label acquires sufficient charge, it converts the label from white to black and starts printing. But the print with direct printing will not last long and is sensitive to temperature and surroundings.

Though the thermal transfer printers are a bit more expensive than regular ones, they will provide the best quality. Direct thermal printing also will be very less. They are easy to handle but come with fewer features.

They do provide only black and white colors only unlike multiple colors with thermal transfer printers.

What are the advantages of thermal transfer printing?

- The biggest advantage of thermal transfer printing is its high quality as compared to the remaining methods like thermal direct printing.

- It gives a chance to print on multiple kinds of materials and products.

- It offers good readability and ensures high resistance to water as well.

- It provides a wide range of colors to print apart from black color. You can choose the color and place the required color ribbon bundle inside.

- The durability of the thermal transfer print is more than the direct thermal printer.

- It can withstand all the temperatures and reactions to various chemicals.

- In addition to paper, it offers a wide range of materials to print like polystyrene, polypropylene, etc.

- The image or print using a thermal transfer printer also cannot be rubbed easily.

- The printer can be used for a longer time with less maintenance throughout.

- It takes less time to print using thermal transfer printing and it makes use of the maximum ink with less wastage.

What are the disadvantages of thermal transfer printing?

- Thermal transfer printers are a bit more expensive than the normal ones because of their complicated and well-developed structures inside.

- While printing, it consumes more time to change the ribbon for printing.

- The ribbons are made of different kinds of material, so they are not eco-friendly.

- Even after printing, the labels inside the thermal transfer printers will remain with heat for a while. This could darken the paper inside. Also, they are sensitive to human touch.

- When the printhead is used excessively, because of the high heat imposed on it, there are chances of damage with low-quality printers.

- To ensure high-quality printing, the substrate and the ribbon material must be compatible with each other.

Conclusion

This is all about how a thermal transfer printer works. We tried to explain the process clearly. Also, we provided the basic information interlinked with the thermal transfer printer.

Hope you have understood how a thermal transfer printer works. Hope you have enjoyed reading our article.

You May Also Like: