Printer companies are trying to introduce new printing technologies day by day. The competition is enormous. This considerable competition allows human society to be presented with numerous printing technologies.

Our principal target is to provide some insight into LCD and DLP printing technologies in this article. People remain confused about the functionality difference between these two printers. A piece of detailed information is given inside this article.

An Expert View Of LCD Printing Technology

When we talk about inkjet printers, we must think about a particular product.

The name of the product is Resin. Resin is the most critical element. Without this crucial element, printer ink can not function properly.

LCD printers use Resin a bit differently. LCD stands for Liquid Crystal Display. For mass manufacture of products, these technology printers are used. LCD printers LCD resin printers already have considerable fanbases in the market.

LCD printers use a monitor that is also built with LCD technology. LCD printers can not work correctly without a light source. This light source is used to cure the resin. Before jumping into the LCD vs DLP printer topic, it is necessary to know about these technologies separately.

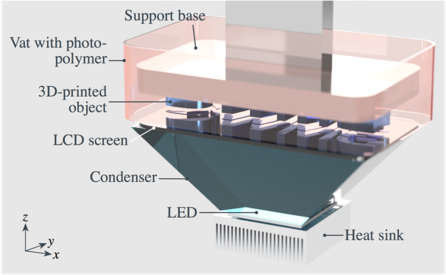

Figure I shows the detailed working procedure of an LCD printer. The first layer consists of a support base. The support base helps carry the weight of things that will be scanned. The important thing about an LCD printer is the LCD screen.

The LCD screen is lightweight and provides a high-level scanning function. The scanning function provides better quality printing. The screen is environment friendly as no emission of radiation is available here. New technology is introduced in the LCD screens. The anti-glare technology allows the LCD screen to work precisely.

The consumption of power is shallow. As a result, the yielding per page is also very low. Distortion is also another primary criterion to judge a printer. In the case of LCD printers, the distortion is zero from the magnetic field.

LCD screens provide zero screen burn technology. This zero burn screen technology ensures the demand for LCD printers is increasing day by day. These advantages help conclude the LCD vs DLP printer topic more readily.

After the LCD screen, there is a condenser. The condenser absorbs the excess heat and cools them. This condenser makes sure no heat issue is available inside the printer. After the condenser, there is a series of light-emitting diodes, a.k.a LED.

The canon advantage of LEDs is that they are cheaper than the Laser. If you have ever heard the term 1000dpi LED printers, then there are 1000 LEDs available per inch. The LED price is lesser than laser, whereas the printing quality is also better.

So, the parts as mentioned above constitute an LCD printer. Next is to learn about the pros and cons of LCD printers to solve the battle between LCD vs DLP printers.

Significant Advantages Of LCD Printers

When we are thinking about buying a printer, it becomes rigid due to so many printing technologies available here in the market. Our task is to guide you in choosing your perfect printer.

HP is the most famous brand for producing LCD printers. These printers are not only durable but also very user friendly. These printers allow the printing of 3D objects properly with no issue that can harm the environment.

Time to discuss some of the significant pros of LCD printing technology. Without knowing the advantages, you can select whether you should buy LCD printers. After learning about the edges, we will also learn about the prime disadvantages of LCD printers.

Without using extra words, it is time to jump into the benefits of LCD printers. The LCD vs DLP printer will be more interesting after that.

- The emission of radiation is harmful to the environment, human skin, and health. After launching LCD printers, the first concern was how much radiation they would emit. But this technology provides zero-emission of radiation.

- One of the worst things about today’s printers is they consume a tremendous amount of energy. LCD printers are an exception in this case. LCD printers consume a significantly lower amount of energy, thus leading to lower costs in maintenance.

- When printing, it is essential to maintain the geometric shape properly. In the case of the LCD printers, no geometric distortion is available. This ensures that it will always provide high-quality printing no matter the object’s shape.

- The rate of zero flicking and an excellent contract is also another primary domain of LCD printers. When customers learn about these features, they are attracted. For mass printing, LCD printers are well known everywhere.

- Installation and maintenance are straightforward in the case of LCD printers and LCD resin printers. Almost all companies provide user manuals on how to operate LCD printers properly. The installation procedure is also effortless in the case of LCD printers.

- LCD printers are well capable of working in any sort of operating system. The operating system, known as system software, does not always feel friendly with all printers. LCD printers ensure that the operating system will deal with it more familiarly.

- LCD printers provide printing at a cheaper rate. As mentioned, LEDs cost less than Lasers. The yielding of each page is low in the case of LCD printers. The low power consumption also allows printing at a significantly cheaper rate.

- LCD printers are available on both Impact and Non-Impact versions. As a result, customers can find their needed printers easily. Availability on both versions helps the LCD printers to gain popularity quickly.

- Another significant advantage of LCD and LCD resin printers is that they provide a higher number of LEDs than other technologies. The number of pixels is also higher than other printing technologies. Printing gets sharp with the increasing number of pixels.

- Air pressure hampers the technical parts inside a printer. LCD printers are built so that air pressure can not affect the interests of the LCD printers.

- Lighter in weight allows the printers to charm their customers. LCD printers are easy to carry. The printers are environmentally friendly. The safety manual is very elaborate as a result lesser accidents take place with LCD printers.

The major advantages of LCD printers are discussed above. Technology can not be judged based only on benefits. When we are dealing with printing technologies of different domains,we also need to focus on disadvantages.

Before focusing on the disadvantages, you find some of the best LCD printers. You can find the details of the printers on Amazon.com. For betting understanding, kindly visit the following link.

LCD Printers On Amazon.

The amazon.com site consists of thousands of LCD printers. Customers can focus on their preferred printer and learn the details from there. LCD printers have a high reputation for long lastingness. For the betterment of customers, we have listed some of the best LCD printers:

- OfficeJet Series of HP

- ColorJet Series of HP

- Canon ultimate Pro LCD printers

- Cura High Profile LCD printers

- Philips HP pro max Color LCD printers

Customers can focus on the above-mentioned series. Each brand has its own facilities. Now we can focus on some of the disadvantages shown by LCD printers.

Disadvantages Of LCD Printers

Each good thing has a bad side. LCD printers are no exception. The major disadvantages are listed below for a better understanding of readers.

- Though LCD printers are known for their economic behavior, they are more expensive than CRT technology printers. CRT technology is a clear competitor here.

- Sometimes printing has some blur effects. The blur effect leads to customer dissatisfaction. To remove the problem, technology is trying new things.

- The rate of refreshment is higher than any other printer. As a result, things are not getting stable at one time.

- The most annoying thing reported by customers in the case of LCD printing technology is that the response is not always fast. The later response is conveyed on various social media platforms.

- Another significant issue is LCD printers often feel discomfort while printing objects having a black or gray color. Though compatibility with other colors is tremendous, this is another major issue reported by customers.

After gathering knowledge about LCD printers, it is time to learn about DLP printing technology; else, the LCD vs DLP printer’s argument will remain unsolved.

An Expert View Of DLP Printers

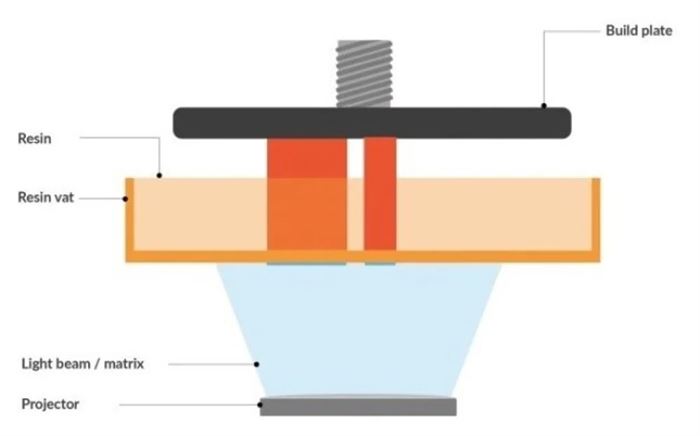

When people know about the working procedure, they become shocked. DLP is a printing technology that produces photopolymers rapidly. The elaboration of DLP is Digital Light Processing. SLA VS DLP is also another central argument in the field of printing.

DLP printing technology is mainly recognised for extreme complex printing. It can scan complicated shapes used primarily in toys or in other objects. For mass printing usually, DLP is not recommended. SLA VS DLP can solve this problem more efficiently.

DLP printers are mainly known for accurate printing with all complex functions. This technology uses an extensive amount of resins to produce an object for printing. A light beam inside DLP printers can configure the necessary things to be integrated.

Major Advantages Of DLP Printers

To solve the LCD vs DLP printer argument, it is required to gather knowledge about the advantages of DLP printers. Some of the significant benefits are discussed below with proper explanation.

- When customers look for printers that can print with 100% accuracy, they must use DLP printers. Every printer can print objects with a 100% accuracy level. The printers are exact and accurate.

- DLP printers are affordable. Laser printers are always expensive, but the price is not high when we are talking about DLP printers. DLP printers are well known for less pricing.

- The yielding of the papers is very high in the case of DLP printers. DLP printers can print objects more accurately.

- DLP uses polymers while printing. The procedure of printing through DLP is speedy. Polymers are the real reason for making this thing swift.

- Though DLP printers produce heat yet, these printers are also environmentally friendly. The Printer manual provides all the necessary details about the printers.

- DLP printers use Resin extensively. As a result, it uses the proper amount of ink when it is about to print heavy borders.

- Warping large objects using DLP printers is very easy. This technology-focused on this feature, especially while implementation.

- DLP printers can cope with any operating system easily. There is no such report regarding the incompatibility with the system software.

After learning about the advantages, a reader can be enthusiastic about learning the disadvantages of this technology. The penalties are collected from social media sites and in vlogs. The disadvantages are listed below:

- The main issue with the DLP printers is the heat issue. Due to the excess use of polymers, this printer produces massive heat. In the absence of a cooler, this heat can be dangerous and may cause accidents.

- For mass production and printing, DLP printers are not always recommended. Producing mass printing needs to work for a longer time. In the case of DLP printers, the longer it stays alive, the more heat it makes.

- The parts of the DLP printers can not be put under sunlight. Because under sunlight, the aspects of the DLP technology start degrading. The performance becomes less effective after the incident.

- DLP printers use Resin too much. Because of the excessive use of Resin, the printing cost started increasing. Recent technologies are trying to solve the issue.

- Unlike FDM technology, DLP technology printers are not cheap enough, and The FDM technology printers have a tremendous advantage here.

- The parts inside the printers have a higher impact while buying a printer. The FDM technology printer parts are superior to the DLP printing technologies.

For learning the price and other properties, customers can visit the given link below under this line.

Best DLP Printer On Amazon.

Solving The Ultimate Mystery: LCD VS DLP Printers

After analyzing everything, customers might fix their minds before reading the below section. Now a summary will be shown in front of the users about the detailed pros and cons of these printers. Each printer has its facility and its own problems.

LCD printers can be a superb choice for mass and frequent everyday printing for mass printing and daily routine printing.

On the contrary, DLP printers are known for their artistic printing with natural shapes. Complex architectures can be printed easily using DLP printers.

A table is given below to find the significant differences between these printing technologies. Both technology printers are available in impact and non-impact versions. Using the table, a customer will find the truth about the LCD Vs DLP printers.

The first column of Table I is the attributes of the printers. Vertically two more columns are decorated to indicate the printers’ capability individually based on the given feature.

| Attributes of printers | LCD Printing Technology | DLP Printing Technology |

| Heat Issue | Not available | Available |

| Presence of Polymers | No use of polymers | Excessive use of polymers |

| Availability of printing parts | Widely available | Widely available |

| Presence of LED | Present | Not present |

| FDM | Not available | Yes general |

| Yielding of pages | Higher number than DLP printing technology | Lower number than LCD printing technology |

| Mass Printing | Is a good option for mass printing | Usually not recommended for mass printing |

| Sharp Edge Technology | Not available | This unique feature is available |

| Sound Issue | No | No |

| Laser Film Presence | Absent | Present |

| Presence Of InkJet | Present | Absent |

| Printing Capacity | High | High |

| Dark Or Ghost Stop Issue | No | No |

| Printing Medium | Duplex | Duplex |

| Duplex Printing (Automatic) | Yes | Yes |

| Quality Of Color Printing | Very good in the case of color printing | Very good in the case of color printing |

Table I – Detailed Difference Between LCD Printers And DLP Printers

FAQ

- What Is The Difference Between LCD And DLP 3D Printer?

Both printers have their advantages. The main difference between these two printers is that DLP uses a project for printing where LCD uses an LED screen. For mass printing, LCD is better, but in the case of sharp printing, DLP is better.

- Are LCD 3D Printers Good?

LCD printers are perfect for fast and mass printing. The yield of papers is much higher than other technologies. These printers provide enough safety measures with a detailed instruction manual.

- How Long Does A Resin Printer LCD Last?

Usually, resin printers are very efficient and long-lasting. A Resin printer has an average lifetime of 10 – 12 years.

Conclusion

Laser Vs DLP printer is a topic that is still not solved correctly. Yet, in this article, we have tried to elaborate on the details regarding this topic. LCD printers are preferred for mass printing, whereas DLP printers are suggested for delicate edging.

For the betterment of customers, we are trying to add as necessary features as possible—best of luck with the following article.