Thermal printers are considered to be workhouse machines for many organizations or workplaces. Thermal technology can be a great option for media and application flexibility, and low maintenance. But have you ever wondered how do thermal printers work?

Well, here in this article we are going to share how thermal printers work, their advantages and disadvantages along with other necessary details. So let’s get started.

How Does Thermal Printer Work

Before we start with the process of how thermal printers work, it is necessary to know what a thermal printer is.

What is a Thermal Printer?

A thermal printer is usually a printer that uses a heated print head to produce black text or images. For thermal printing, no ordinary paper is used. A special type of paper is used named thermal paper.

These papers contain thermal pigments, which are initiated by the heated print head. Or, the printhead transforms solid ink from ribbon and pacts it with the medium.

Thermal printers are usually used for making labels, barcodes, etc. There are different models available. Such as Mobile, Desktop, and industrial thermal printers.

How Do Thermal Label Printers Work?

Do thermal printers use ink? Do thermal printers print in color? So many questions, right?

Well, how do thermal label printers work? You have to know about their two working methods:

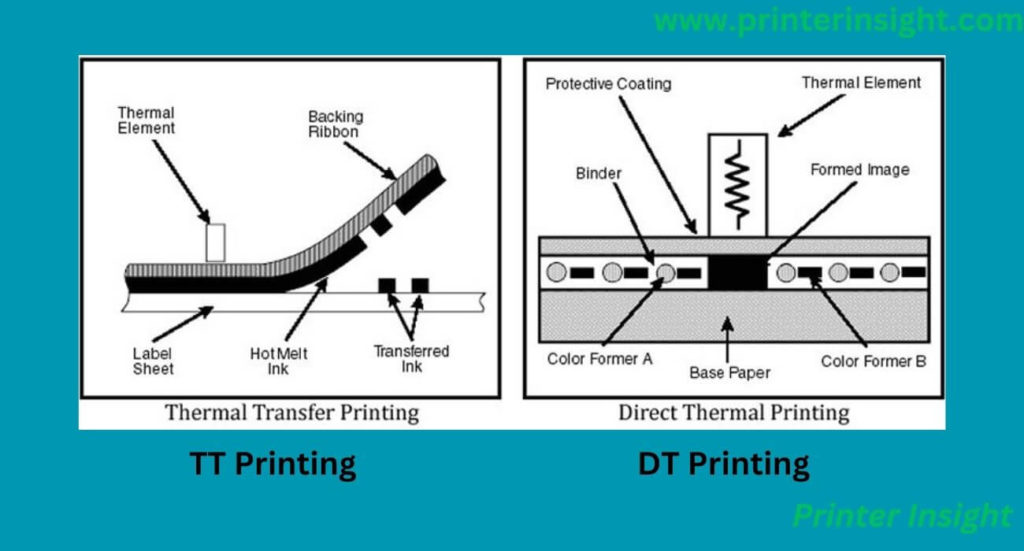

1. Direct Thermal Printer

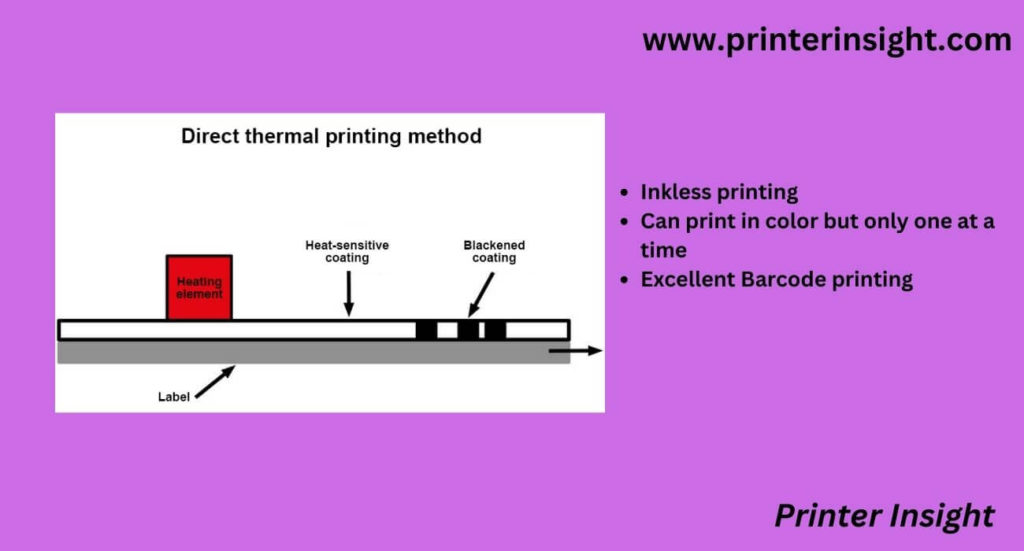

You don’t need any ribbon, toner, or ink in the direct thermal printing process. Instead, the printhead applies pressure and heat directly into the heat pigments or sensitive heat surfaces of thermal papers.

Then the pigments of thermal paper activate, they blackened when heated and produce texts or images.

As there is no ink, toner, or ribbon used, maintenance cost is low for direct thermal printing. But this process has some drawbacks too. The produced media of direct thermal printing are very sensitive to heat.

You will also notice receipts or labels will fade over time. Not only that, in direct thermal printing, you can use only one color at a time.

Features At A Glance

- No ink required

- Can print in color but only one at a time

- Barcode printing

2. Thermal Transfer Printing

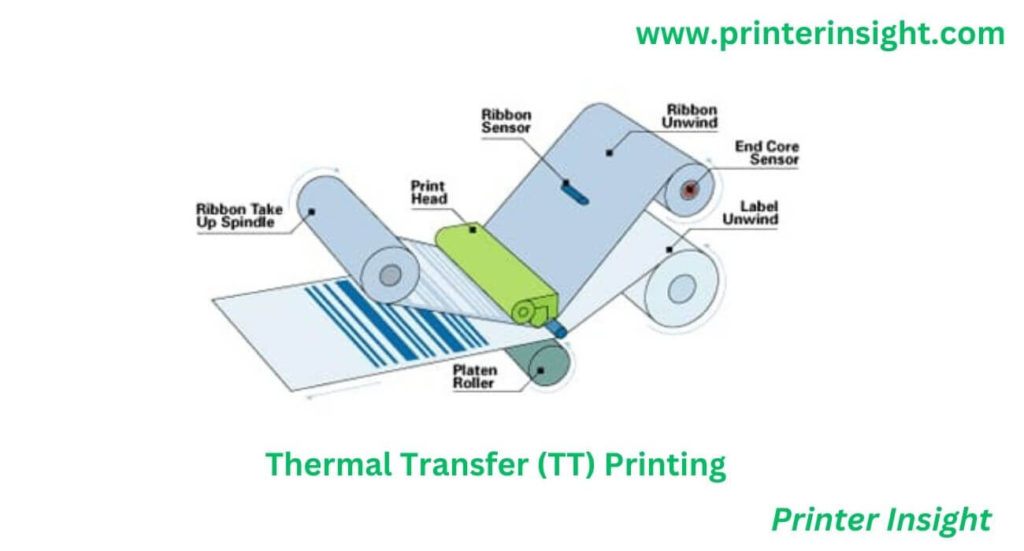

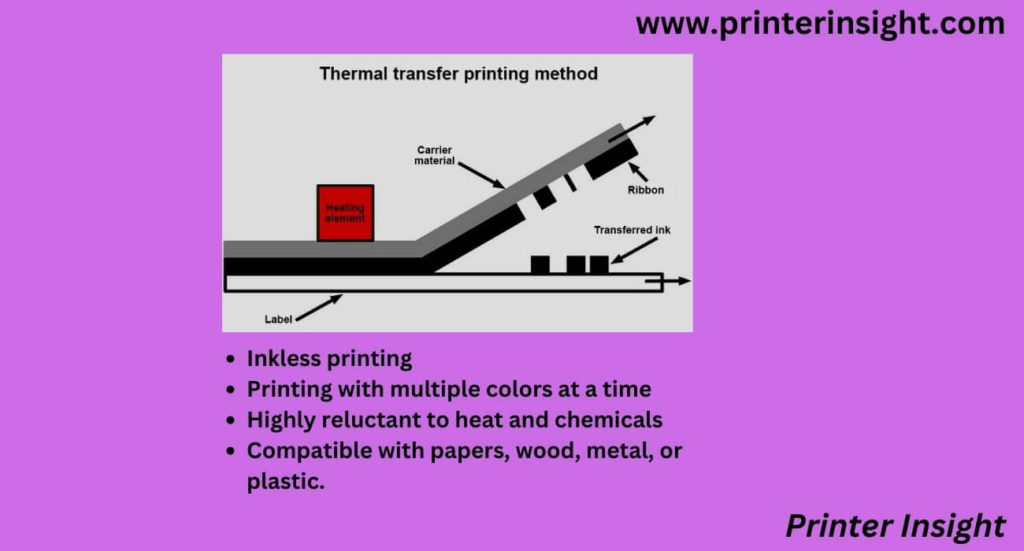

The operating mechanism of thermal transfer printing is not the same as direct thermal printing. In this method, the print head of these printers presses a wax contained ribbon onto the heat-sensitive surfaces of thermal papers.

Then this wax substance is melted, exposed to ink and after that, they are transferred to the printing materials and dried.

This method provides more durable and quality printed materials than direct thermal printing. The greatest advantage of this method is the printed labels will not fade over time easily. Also, you can use multiple colors at a time.

But due to ribbons, maintenance cost is higher than direct thermal printing. Moreover, you have to replace ribbon, a key component of thermal transfer printing, often. This also adds to the cost. Though the printers are durable, the moving parts make them vulnerable to operational uses.

Features At A Glance

- No ink required

- Can print in multiple colors at a time

- Highly reluctant to heat and chemicals

- Not limited to papers only. In other words, you can print on wood, metal, or plastic also.

Thermal Printers Advantages and Disadvantages

Trying to guess if thermal printers are perfect for you compared to other printers? Then you have to know the pros and cons of thermal printers in the first place.

Advantages of Thermal Printers

Some of the biggest advantages of thermal printers are

- Low-Cost Maintenance: You don’t need to have or ensure any ribbon, cartridges, or think about how to remove printer ink from paper smoothly. Only the media is enough to run the printer smoothly.

- Portability: thermal printers are portable and light in weight. For this reason, these printers have versatile uses. You can take them anywhere such as offices or warehouses with ease.

- Compatibility with Modern Technology: Thermal label printers are superbly compatible with smartphones, tablets, laptops, desktop PCs, WiFi, and Bluetooth. Besides, you can easily integrate thermal label printers with design apps used in desktops, laptops, or software development kits.

- Great printing Quality: Impressive printing quality with high speed is another great thing about these printers. You can expect smudge or befoul printings in milliseconds.

- Longevity: As there are fewer moving parts of these printers. It makes them easy to maintain and things break less than others. The print head of these printers lasts for about 10 years.

- Clear and Scannable Label Printing: Thermal label printers can deliver excellent barcode and label printings which are extremely clear and easily scannable. That’s why you can use these printers for business purposes.

Disadvantages of Thermal Printers

To know a product well, you have to consider the negative sides also-

- Direct sunlight and heat affect thermally printed labels. Sunlight and heat can damage label quality, even label identifying boxes fade if they are stored for a long time.

- If you keep labels in the heat for a long time, they turn fully black. So it is better to store them at room temperature.

- Direct thermal printing uses one color at a time whereas thermal printers allow more colors at one time.

- Thermal printers are way costlier than other inkjet printers. Though average thermal printers cost up to $300-$500, industrial thermal printers cost more than thousands. Also, there is a risk of damaging print heads due to heat.

Applications of Thermal Printers

- Transportation and Logistics

- Cross-docking and stocking

- Picking and packing

- Shipping and receiving

- Inventory management

- Proof of delivery

- Rental car return

- Manufacturing

- Compliance labeling

- Parts management

- Equipment maintenance

- Traceability

Well, we think you have got answers to all of your questions. So before giving our final verdict, let us look at some questions related to this article.

Frequently Asked Questions (FAQs)

- How Long do Thermal Printers Last?

The lasting period for thermal printers depends on the type of ribbon you use. If you are printing with direct thermal paper, it lasts about 7-15 years. On the other hand, if you are using thermal printing papers, it lasts for 20-25 years. It is 20 years for Synthetic media. But how long your printer will last depends on how well you store the machine.

- Do Thermal Printers Need Special Paper?

Yes, thermal printers require special papers as their mechanism is based on inkless technology. They use heat to produce imprints. These thermal papers contain heat-sensitive surfaces. By heated printhead, these pigments are activated to produce imprinting works.

- Do Thermal Printers Run out of Ink?

As thermal printers don’t use inks, running out of inks is out of the question. They use a special mechanism of heat to produce printing works. In Thermal Transfer Printing, heat is used to melt the ribbon for printing.

Final Words

We hope this guide on How Do Thermal Printers Work will be a great help for you.

Thermal printers have a variety of users in different industries; such as transportation and logistics, packing and pickings, shipping and receiving, manufacturing, etc. So, in a word thermal printers can be said to be workhouse machines for many industries or organizations.

So if you are willing to buy any thermal printer, then research for a little bit more, look at reviews of different models along with their pros and cons. Then you will be able to get a perfect thermal printer for your workplace.

That’s it for today. Have a very nice day!